GNY Casing Clamps for Drilling

GNY Casing Clamps for Drilling

Casing Clamps, a mechanical device designed to facilitate the hoisting or suspension of casing in a borehole. Clamps are made by forming a half circle in a heavy steel plates and bars.

The Company was an early pioneer in the development of hydrant type aircraft refueling equipment and related aircraft ground support equipment. Experience in this field led to the designing and manufacturing of Aviation, Oil and Gas Equipment. The company had traded under the name Garsite TSR.

The Deer Park facility remained in New York as Garsite International until in December 1995, when GNY Equipment, LLC (GNY) was spun-off to an independent status, bringing with it, almost a half-century of experience in aviation fueling, in liquid, air, oil and gas equipment. The people at GNY have been manufacturing fueling equipment for over three decades.

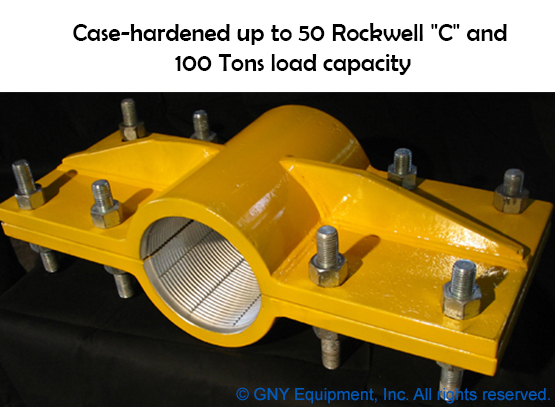

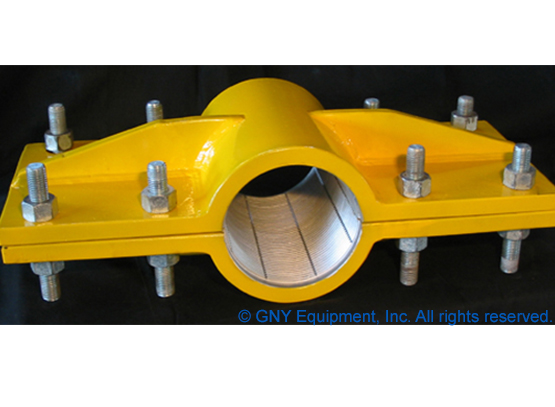

GNY Equipment, offers Casing Clamps, a mechanical device designed to facilitate the hoisting or suspension of casing in a borehole. Clamps are made by forming a half circle in a heavy steel plates and bars. When bolted tighter, in pairs, the bar fits around the outside and tightly grips the casing. The size of the clamp is determined by the outside diameter of the casing to be handled. Generally used for Drilling Operations.

GNY Equipment, offers Casing Clamps, a mechanical device designed to facilitate the hoisting or suspension of casing in a borehole. Clamps are made by forming a half circle in a heavy steel plates and bars. When bolted tighter, in pairs, the bar fits around the outside and tightly grips the casing. The size of the clamp is determined by the outside diameter of the casing to be handled. Generally used for Drilling Operations.

- Size: From 4-½” OD, 7” OD, 9-5/8” OD, and higher sizes up to 20”OD Casing pipes as per API 5A.

- Casing Clamps are designed as per API specification for casing pipes.

- Material of Construction:

Carbon Steel Body: ASTM Plate A829 Gr. 8620 or equal, high-yield steel. And other material upon request for specific application.

Studs and Nuts: High tensile A193 B7 and A194 2H (heavy duty) with spring washers. Clamps are designed and supplied with total of eight (four each on both sides) of high tensile studs (min. 25mm /1”) size with hex nuts and washers on both sides.

- Suitable for mounting on 4-½”OD, 7”OD and 9-5/8”OD etc. Casing with built-in, machined out, Case hardened unidirectional unique grip (specially designed grip profile of ¼” pitch x 4 Grips/inch length) Pressure relieved by three/four slots of ½” wide are provided at right angles to grip.

- Hardening: Case-hardened up to 50+/-2 Rockwell “C” (equal to 450-480 BHN hardness).

- Stress Relieved: All clamp’s body are stress relieved after cold-forming and welding of reinforcement webs before case-hardening.

- Over-All-Length of the clamps: for 7” and 9-5/8”OD, overall length is 12.25” length.

- Lifting lugs/ eyes/ handles are provided for easy installation and safety.

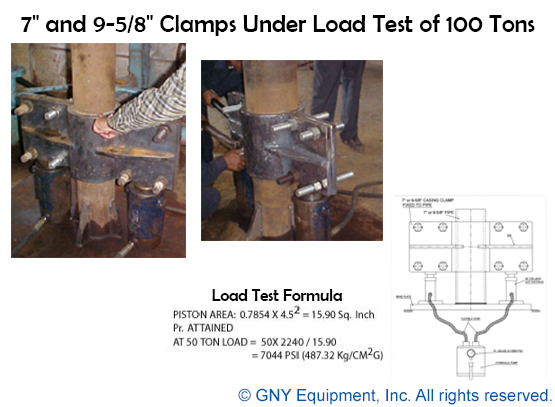

- Loading Capacity: 50+Tons and higher loading capacity. Both sizes of 7” and 9 5/8” clamps are proof tested at factory witnessed by third party inspection agency.

- Special Tests: Bending moment or load tests have been conducted during the R&D (research and development) and other required tests can be conducted for specific sizes.

- Painting: All clamps are epoxy spray-painted outside and rust preventive red-oxide coated inside. All fasteners are Zinc plated (PTFE coated fasteners are also available).

- Casing Clamps are suitable for application in standard service conditions,

application in Marine environment and storage in tropical conditions. - Provided with documentation (MTR) and with installation, operation manuals and storage instructions.