GNY Fuelers: Midi Fueler

GNY Fuelers: Midi Fueler

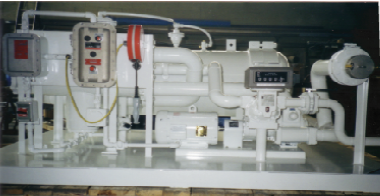

Model: 1736 Midi-Fueler

GNY Midi-Fueler is designed to filter, meter and dispense gasoline, avgas, diesel or aviation turbine fuels at flows up to 300 GPM from a stationary, compact unit. The basic unit can be fitted with a variety of options to suit individual customer needs. The basic unit can be fitted with a variety of options to suit individual customer needs.

GNY Midi-Fueler is designed to filter, meter and dispense gasoline, avgas, diesel or aviation turbine fuels at flows up to 300 GPM from a stationary, compact unit.

- Cabinet:

Unpainted 16 gauge stainless steel housing, removable rear access panel, hinged roof with hold open bar for access, dual/single front main access door(s) with locking handles keyed alike. - Equipment Base:

Heavy-duty channel frame with deck plate for equipment support. - Inlet Strainer:

Cast Iron construction, located on suction side of pump, 40 mesh basket. - Pump/Motor Starter:

Positive displacement type pump, cast iron construction/explosion proof electric motor and manual starter. - Filter/Separator:

Two (2) stage cartridge type F/S, internally epoxy coated steel ASME vessel, victaulic inlet and outlet, air eliminator, differential pressure gauge, (Direct reading piston type) and thermal pressure relief API 1581 Group II, Class B, Third Edition. - Deadman Control Valve:

GNY Manufactured. - Meter:

Positive displacement type, non-ferrous construction, large numerical counter. (SPECIFY GALLONS OR LITERS) - Hose Reel:

Heavy-duty hose reel, 115V AC, single phase, 60Hz explosion-proof electric rewind, non-ferrous swing joint/internals. - Hose:

50′ length hose certified for aviation fueling coupled male x male non-reusable couplings. - Nozzle:

Overwing nozzle for aviation service, rigid drop tube, strainer, dust cap, swivel, grounding wire, non-ferrous construction. - Static Reel:

Heavy-duty aviation type, cable length to suit hose length, 100 amp alligator clamp. - Piping:

Piping upstream of filter separator to be steel, piping downstream of filter to be aluminum to prevent contamination. Victaulic couplings are provided to facilitate disassembly. - Electrical:

All wiring in rigid conduit in accordance with national electrical code for hazardous location. - Finish:

Base, equipment and piping finish painted Epoxy enamel, color white.

| Standard Available 100, 200, 300 GPM | |||

|---|---|---|---|

| Model No. | Flow Rate | Dimensions | Dry Weight |

| 1736-100 | 1736-100 | 78″x96″x46″ | 2300 lb. |

| 1736-200 | 200 GPM | 78″x108″x46″ | 2600 lb. |

| 1736-300 | 300 GPM | 78″x130″x46″ | 3000 lb. |

I am text block. Click edit button to change this text. Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

- Type of fuel to be handled

- Flow rate

- Operating pressure

- Electrical characteristics of power available at site

- Size and type of fuel inlet connection

I am text block. Click edit button to change this text. Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.