GNY Safety Break-Away Couplings (Shear-Pin Design)

GNY SBC – Shear-Pins-Design

Safety Break-Away Couplings | Shear-Pins Design | Collar DesignSBC Applications | SBC Testing | Customer References | Fax Sheet

| Data Table for ANSI Class 150 (Shear Pin Design) | |||

|---|---|---|---|

| Size | Model Number |

Over-All-Length |

Weights |

|

2” |

SBC-2-150-SP |

8.25” |

12.25 Kgs. (27 lbs.) |

|

2-1/2” |

SBC-2.5-150-SP |

8.50” |

18.60 Kgs. (41 lbs.) |

|

3” |

SBC-3-150-SP |

8.50” |

32.65 Kgs. (72 lbs.) |

|

4” |

SBC-4-150-SP |

12.75” |

64.5 Kgs. (142 lbs.) |

|

6” |

SBC-6-150-SP |

12.75” |

78 Kgs. (173 lbs.) |

|

8” |

SBC-8-150-SP |

14.00” |

130 Kgs. (288 lbs.) |

|

10” |

SBC-10-150-SP |

17.00” |

188 Kgs. (416 lbs.) |

|

12” |

SBC-12-150-SP |

20.00” |

230 Kgs. (505 lbs.) |

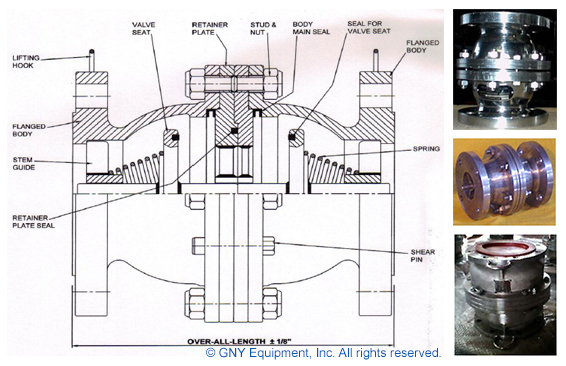

- Sizes: 2″ to 12″NB (50 to 300 mm)

- Built-In End Connections: Flange Ends (2″ to 12″) or Threaded Ends (2″, 2-1/2″ & 3″) or Combination

- Pressure Rating: ANSI Class 150 (PN 20) = 285 PSIG (19.5 Bar) and ANSI Class 300 (PN 50) = 740 PSIG (51 Bar) at temp. -20°F to 250°F (-29°C to 121°C)

- Material of Constructions: SS304/ SS316 Body or CF8 (SS304) /CF8M (SS316) Casting with SS316 Internals.

- Design: In Accordance with Section 5 of API 6H Spec.

- Shear-Pin Breakaway: Designed to Breakaway at Factory-set up 275 PSIG (18.8 Bar) for Class 150.

Higher strength shear-pins available up to 430 PSIG (30 Bar) for Class 150 & 1110 PSIG (76 Bar) for Class 300.

Actual breaking of shear-pins are designed considering Pull-away Force and Internal Operating Pressure. - Seals: Viton®, Buna-N, Teflon® (PTFE), Silicon, EPDM, and Neoprene. Viton® & Teflon® regd. Trade-mark of DuPont.

- Temperature Range: For seal material Buna-N -40°F to 250°F, Viton® -20°F to 400°F,

Teflon® (PTFE) -60°F to 550°F. For low or high temp. applications, contact factory. - Hydro-Testing: Each Half separately internally Hydro-tested as per API 6H Specs.

For ANSI Class 150 (tested at 430 PSIG = 30 Bar) and

For ANSI Class 300 (tested at 1110 PSIG = 76 Bar) at shop before shipping. - Shear-Pin Breakaway Testing: Fully Assembled Breakaway Test at 275 PSIG (18.8 Bar) for ANSI Class 150

and 700 PSIG (48 Bar) for ANSI Class 300 or as agreed. - Functional Flow Testing: Fully Assembled Functional Flow Tests are available and conducted during R&D.

A Third-Party (BVIS/equal) witnessing Hydro-test, Breakaway test & Functional flow-test report, available. - Easy to REASSEMBLE in the field using FREE spare shear-pins, supplied with Installation Instruction.