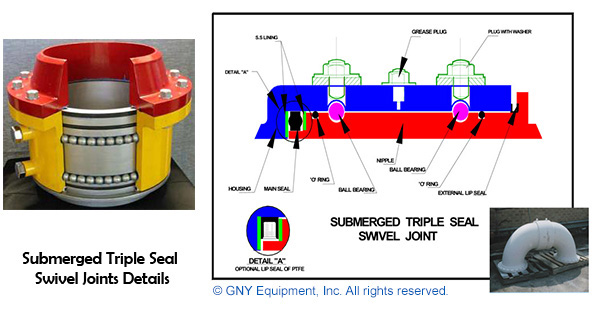

GNY Submerge Triple Seal Swivel Joint

GNY Submerge Triple Seal Swivel Joint

Submerged Skimmers | Submerged Roof Drain

- Size: 2″ (50 mm) to 36″ (900 mm)

Swivel Joints are available in style 20, 30 and 40 with threaded, flanged, butt weld ends connection or combinations, in ANSI 150 to 300 class.Designedas per API Spec. Standard 6H.

- Material of Construction:

Carbon Steel: CS A105/ A515 or A515/A516 Gr. 60/70,

Stainless Steel: SS 304/SS 316(CF8/ CF8M or equivalent)

Aluminum (up to 10”size)

Two different design constructions:

Two Piece Design

Split Flange Design: The main seal can be replaced without dismantling any bearings.

- Ball Bearing, fitted with two rows of widespreadball bearing (Chrome CS or SS)

Combination of roller bearing with ball bearing units are also available. - Heavy-duty load bearing capacity widespread ball-bearing raceway hardened up to 345 BHN (equals to 37 Rockwell “C”) through a special permanent metal hard facing process.

- Seal Contact Faces are overlaid with Corrosion Resistant Stainless Steel (SS) Lining: All CS Swivel Joints are supplied with Special Stainless Steel liningat the main seal faces, on both nipple and housing for longer seal life and smooth rotation.

- Triple Seal Design

Main seal of two different types: O-Ring or Lip Seal.

O-Ring type: Main Seal of O-ring cross section of Buna-n/Viton ®material and O-rings,

Lip Seal type: Main Lip Seal of PTFE (Teflon ®) with Buna-n/Viton ®Insert and O-rings or

Lip Seal type: Main Lip Seal of Buna-n/Viton ®is also available.

A special Inverted Lip seal design for main-seal is also available. - External Lip Seal (for submerged application)

A third additional lip sealspecially designed to provide required sealing for external fluid pressure.

External Lip Seal of PTFE (Teflon ®) or Buna-n/Viton ®.

A special Inverted external lip seal design is also available. - Positive and Negative pressures

Nipple (female) portion is specially dimensionedfor the main seal to remain in the proper functioning position under both positive and negative pressure. - Designed to withstand temperature variations from -40 to 100 Deg. Centigrade A special low or high temperature application is also available.

- Factory Lubricated and Sealed: Lubricated with Special wear resistant high temp. PTFE based lubricant and

Lubricated-for-life (maintenance free) is also available. - Dust Proof

- Hydro testing and Special Testing: All Swivel Joints are Internally Hydro-tested at shop before shipping. The Air test, Vacuum test, Bending moment/Radial load test, Pull load test, Torque test, External Pressure test, Electrical conductivity test and Life Cycle Tests (US Patented) have been conducted during the R&D (research and development) and these tests can be conducted upon request at extra cost.